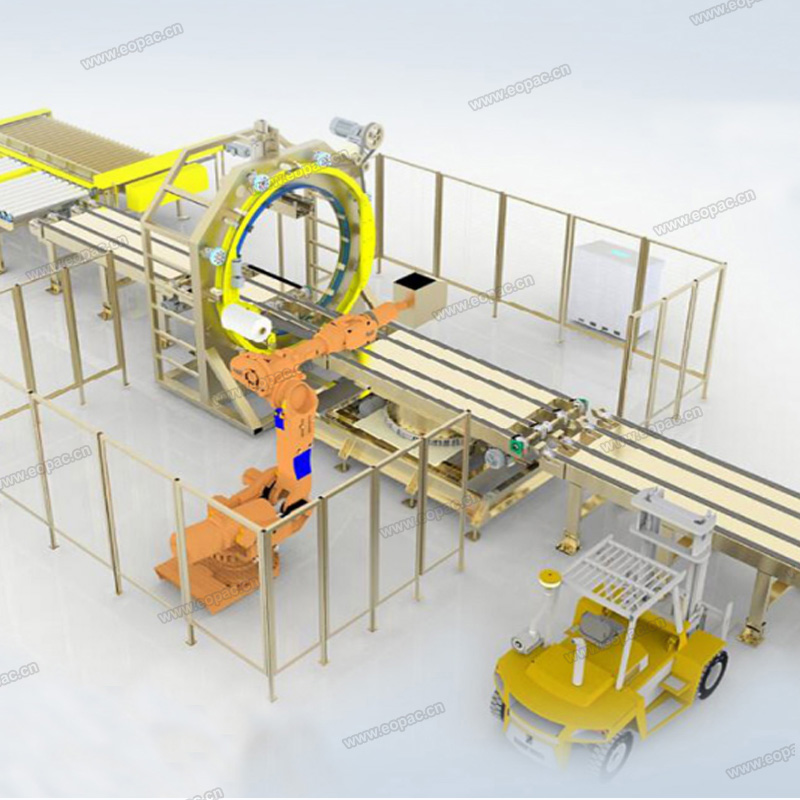

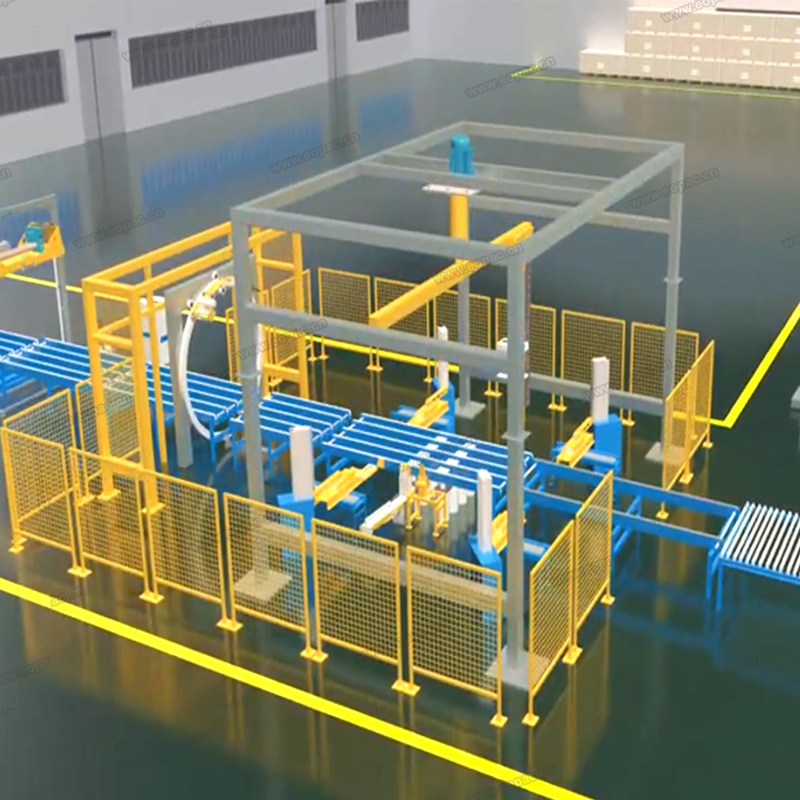

For Boards and Panels, Eopac designs and constructs an entire end-of-line packaging system.

Your boards or panels will be carefully wrapped in stretch film and protected from moisture and dust by this stretch wrapping packaging line.

Reduce supply chain damage by ensuring that your boards reach your clients in good shape.

Packaging Process:

1. The bundle boards be conveyed to the "Spacer feeding unit", this unit will insert blocks underneath the boards according setting

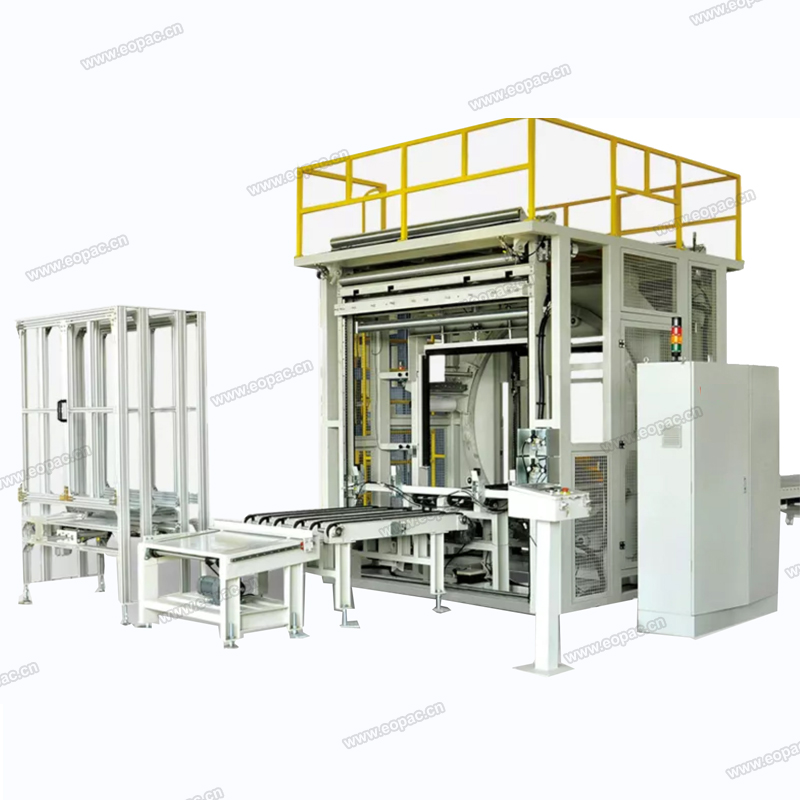

2. Then boards travel to "Horizontal wrapping machine" and apply for packing automatically. (Pack 4 sides)

3. Then travel to "Rotation turntable" to pack both ends sides.

4. After wrapped finished, the wrapped boards will be travel to the outfeed conveyor and wait the forktruck unloading.

Our experienced R&D teams can design the packaging lines according your boards size and requirements.

If you want to learn more information, pls contact us now or drop us an email.

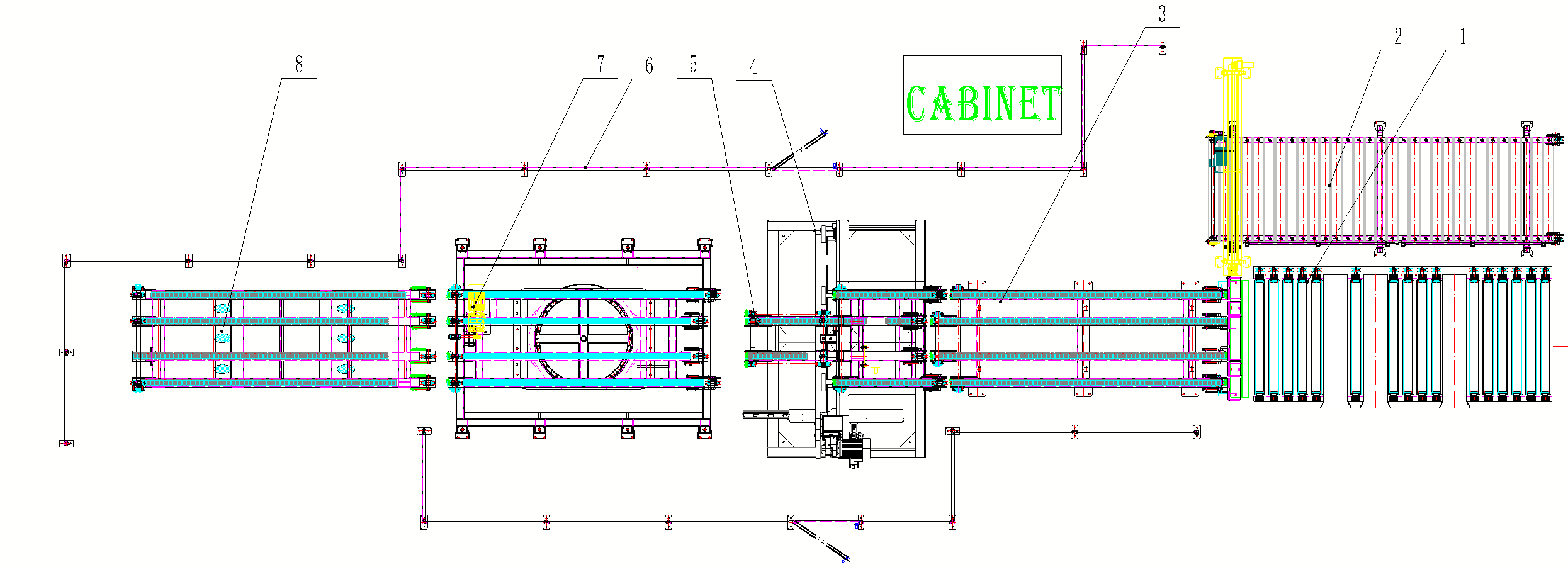

1. Roller infeed conveyor (Forklift loading position)

2. Spacer (blocks) feeding machine (This part is option, can place the spacer by manual)

3. Slat chain conveyor

4. Horizontal wrapping machine

5. Slat chain conveyor

6. Safety fence

7. Rotation turntable to realize 6 sides packing. (This part is option)

8. Outfeed conveyor (Forklift unloading position)