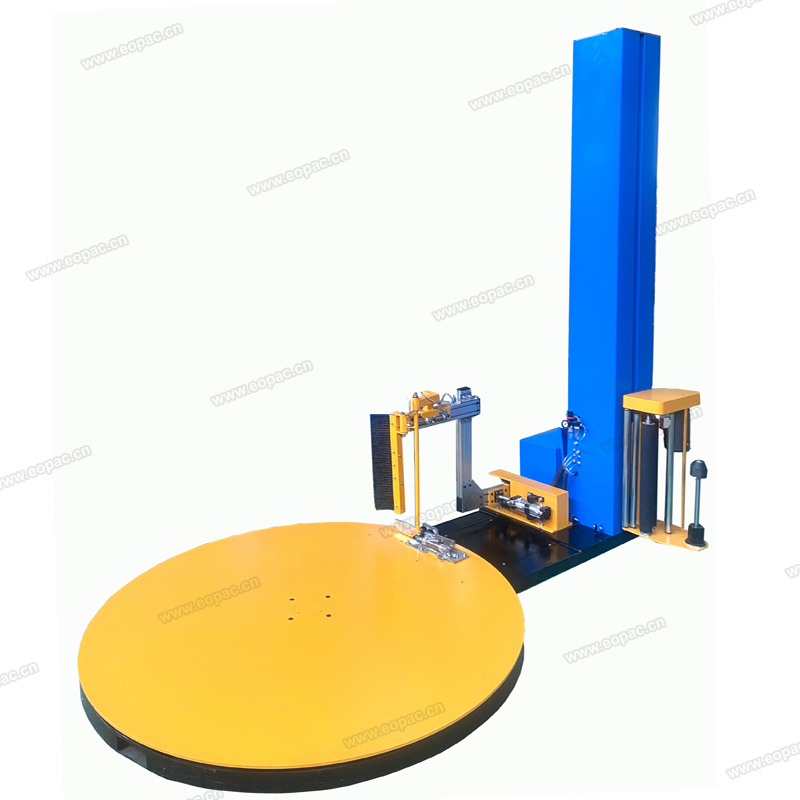

A robotic stretch wrapper applies the film by automatically moving around the pallet.

It is equipped with power pre-stretch film system ensuring perfect pre-stretching and the lowest consumption of film and energy in terms of environmental sustainability.

Self-propelled stretch-film wrapping robot for palletized loads with different shapes, sizes and weight.The robot is suitable for wrapping in multiple spaces.

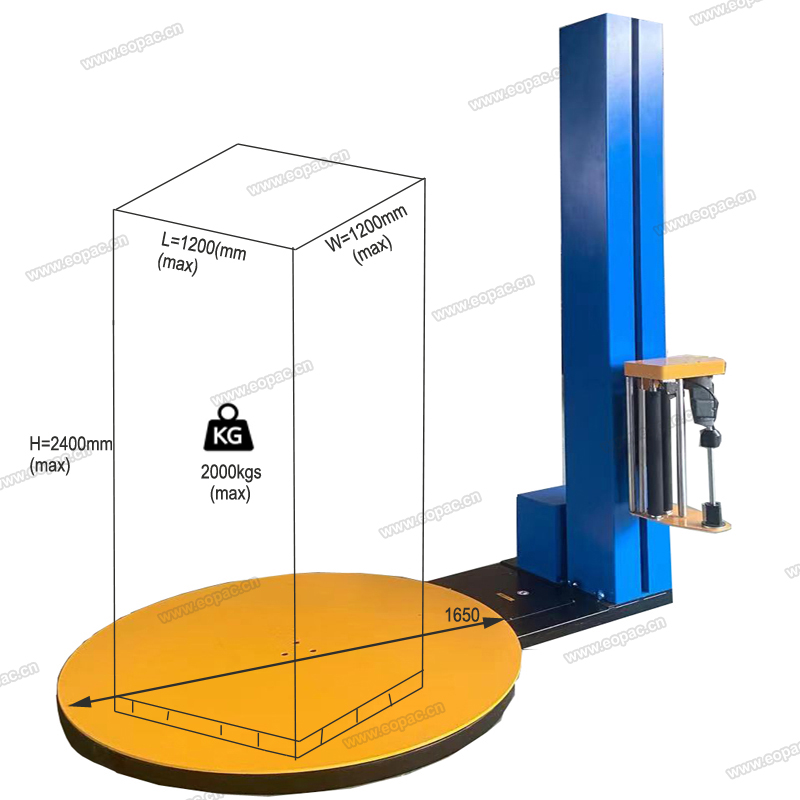

Size of The Loads ( Pallets) to be Wrapped | |

Min load size | 600mm (L) X 600mm (W) |

Max load size | No limit |

Max load height | 2100mm (Option:2400mm) |

Max load weight | No limit |

Machine Performance | |

Wrapper running speed | 0-70m /min adjustable |

Battery | 110AH (12V), 2PCS |

Battery charging time | 8-10 hours |

Running time | 8 hours |

Film tension | Adjustable |

Electrical Features | |

Power supply voltage | 220V ,1P,50/60Hz 10A |

Power | 0.95kw Running motor:0.4kw Film carriage lift motor:0.35kw Film feed motor:0.2kw |

Robot pallet wrapper advantages:

1. There are no restrictions on the maximum size, weight, or shape of palletized loads.

2. There are numerous packaging options available.

3. Use batteries to supply power. A self-walk pallet wrapper has a lot of power and makes very little noise.

4. Save space. In addition to saving workshop and warehouse space, this wrapper's mobility facilitates transportation to the site.

5. Advanced control system using PLC. The control panel's parameters can be set automatically.

6. A battery gauge and charger

7. Excellently efficient film structure that moves quickly up and down.

8. An emergency-stopping front safety anti-collision device

The machine is designed to wrap and stabilize palletized loads of any shape, size, and weight using stretch film and has a high level of packing autonomy and great work flexibility.