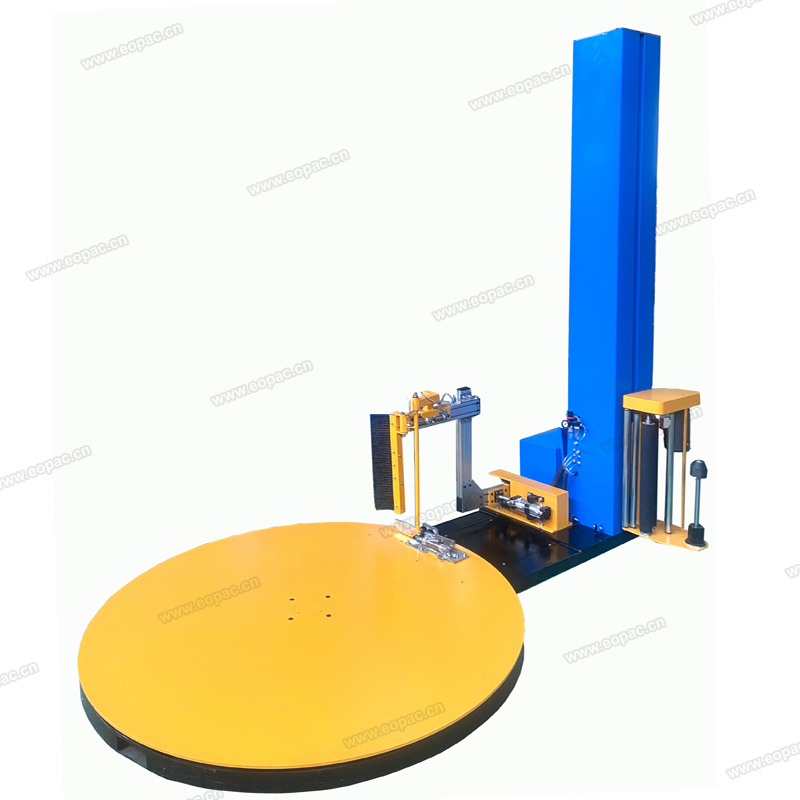

Rotary Arm Stretch Wrapper is best solution for lightweight loads or unstable loads or very heavy loads.

Arm speed is15rpm, Improve packing efficiency. And reduce 30%-50% on packing cost.

Rotary arm will stop by safety bumper and relection PE sensing any objects enter into the rotating area when the machine is running. And there is buzzer and flash light during the machine running..

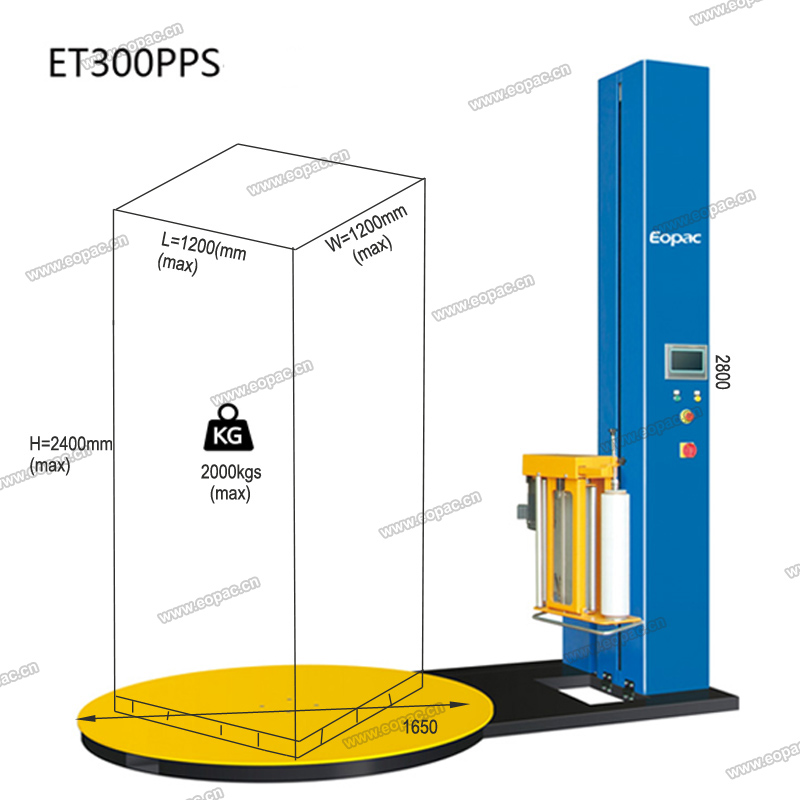

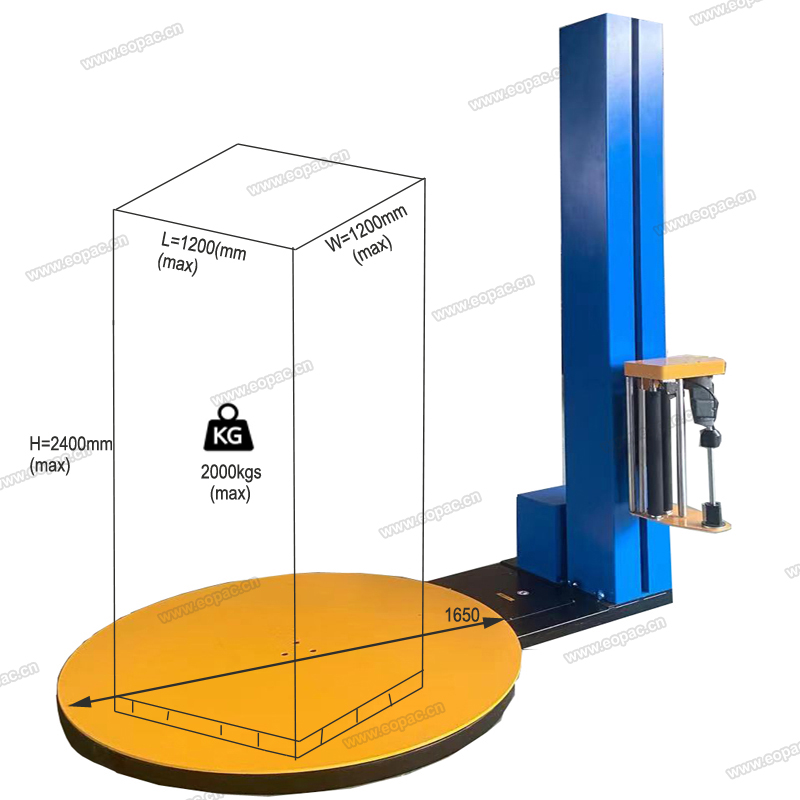

| Size of The Loads ( Pallets) to be Wrapped | |

| Min load size | 500mm (L) X 500mm (W) |

| Max load size | 1300mm (L) X 1200mm (W) |

| Max load size diagonal (Recommend) | 1800mm (70'') |

| Max load height | 2000mm (79'') (Option: 2400mm) |

| Max load weight | Floor Capacity |

| Film Delivery System | |

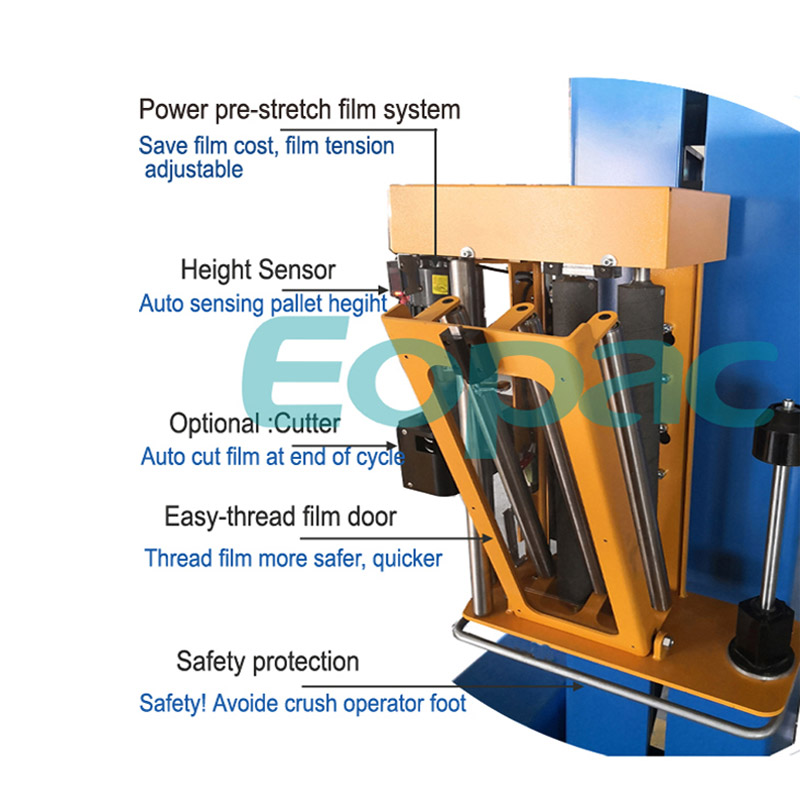

| Carriage | Power pre-stretch Film Delivery System, stretch ratio up to 300%. Help you save Packing cost= Save money!! Carriage door opens for effortless roll change and thread film Film tension adjustable |

| Machine Performance | |

| Packing efficiency | 20-40 loads/hour |

| Load height sensing by photocell | YES |

| Wrap arm soft start & stop | YES |

| Wrap arm rotation speed: | 3-15 rpm adjustable |

| Wrap arm Zone ( rotating inner diameter) | 2180mm (86'') |

| Wrap Arm Safety Stop | Rotary arm stop by safety bumper and reflection PE sensing any obstacle in the rotating area. |

| Carriage Up/down Speed | Adjustable |

| Electrical Features | |

| Power supply voltage | 220 V 1 Phase - 50/60 Hz |

| Power | 1.5Kw |

| Machine weight & size | |

| Machine size | 4050mm (L) 2200mm (W) 3100mm (H) (170'' L X 87''W X 122'H') |

| Approximate Machine net weight | 1000kg |

| Stretch Film Roll detail | |

| Film Max. external diameter (D): | 230 mm |

| Internal diameter (d): | 76 mm |

| Film width: | 500 mm (20'') |

| Film thickness: | 17-35 µm |

Options available to custom build to meet specific needs

1.AUTO FILM CUT-OFF

Cut film tail automatic after stretch wrapping cycle finished, save operator time

2. TOP PLATEN

Add mortorised top platen to protect the unstable products during stretch wrapping