| Model | EH-3015CM side sealer | ST-5030LG shrink tunnel |

| Power | 4kw | 16 kw |

| Power Supply | AC 380/220V 1/3PH 50/60Hz | AC 380/220V 3PH 50/60Hz |

| Max Packing Size L×W×H | W+H≤450mm H≤150mm | W400×H200mm |

| Tunnel Size L×W×H | / | 1500×500×300mm |

| Sealing Blade Length | 450mm | / |

| Packing Speed | 80-100pcs/min. | 0-20m/min |

| External Air Source | 6-8kg/cm2 | / |

| Shrink Film | POF | POF |

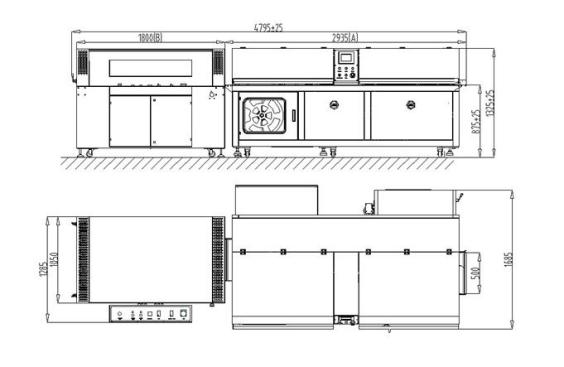

| Machine Size L×W×H | 2735×1480×1300mm | 1860×985×1315mm |

| Packaging Size L×W×H | 2785×1530×1450mm | 1910×1035×1465mm |

| G./N. Weight | 1200/1100kgs | 493/453kgs |

●This machine uses advanced side sealing and continuous motion horizontal sealing which have continuous sealing function. Servo control series realize perfect shrink wrap with high efficiency;

● Servo motor action performs stable, reliable, continuous packaging process in high sped running, smooth transport without product move and stop;

●Equipped with self-adapt feeding system adjust feed speed automatically according to speed of host machine;

●Whole system be standby status when feed by manual or miss feeding, switch-on automatically fill to continued product feeds.

●Color touch operator interface accomplish all working date easily, the panel with date memory for various products allows quick changeovers by simply calling up the needed date from the database. Error of shows on screen with automatic inspect function make easier for operator to do emendation;

●Continuous cross seal without gap at sealing line, waste film can be saved 10%~20% compared with other traditional equipment which save customer cost a lot;

●Whole performance controlled by servo motors includes feeding, film releasing, sealing, shrinking and out feeding, make it smooth running in high speed;

●Able to increase logo locate function for printed film;

●Equipped with suitable feeding system to connect customer production line for different products, realize fully automatic packaging to save labor cost;

●ST-5030LG adopts advance blowing from the bottom of the tunnel, full use of heat to arise energy efficiency. Frequency inverter controls blowing, adjustable blowing direction and volume from bottom.

●Visible window shows shrink process in tunnel, the top of tunnel can be opened for easy clear and maintenance;

●Optional belts feeding or fingers pushing conveyor for meeting products or customer’s requests;

●Adjustable conveyor speed which controls equal distance among products make sure seal consistent sealing;

●Applicable for mass packaging like CD, photo frame, books, magazine, electronic products etc.

LAYOUT

We can offer customized machine according to the size of your products!

We can replace the configuration according to your needs!