| Model | EF-400LA | ST-4525 |

| Power | 2.2kw | 9kw |

| Power Supply | AC 220V 1PH 50Hz | AC 380V 3PH 50Hz |

| Max. Packing Size L×W×H | L+H≤530mm W+H≤430mm H≤140mm | 1000×300×200mm |

| Max. Sealing Size L×W×H | L550×W450mm | / |

| Packing Speed | 15m/min. | 0~20m/min. |

| External Air Source | 6-8kg/cm2 | / |

| Shrink Film | POF | POF |

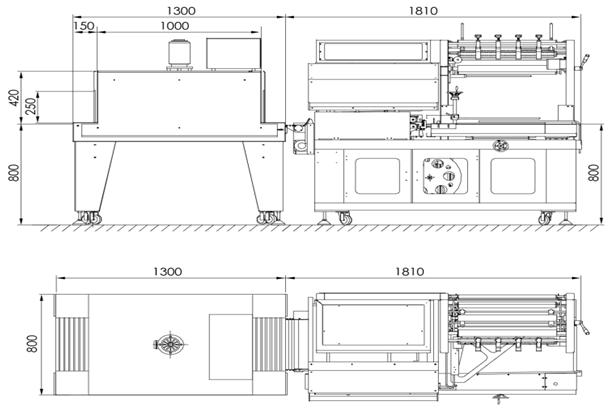

| Machine Size L×W×H | 1810×880×1600mm | 1300×800×1520mm |

| Packaging Size L×W×H | 1860×930×1750mm | 1350×850×1670mm |

| G./N. Weight | 483/453kgs | 270/240kgs |

● EF-400LA is a fully automatic unmanned operation "L" type sealing machine which is widely used in mass production packaging line with high efficiency. Automatic film feeding punching device, manually adjustable film-guide system and feeding conveyor platform make the machine suitable for different width and height items. EF-400LAC has closely connecting function which specially designed for small items;

● Sealing knife uses the aluminum knife with DuPont Teflon which is anti-stick coating & anti-high temperature. So the sealing will not have cracking, coking and smoking with zero pollution;

● Equipped with imported photoelectric of horizontal and vertical detection for choice to easily finish the sealing of thin and small items;

● Automatically-feeding: the length can be auto adjusted by the sensor and time relay. Matched the reduction motor makes the waste film automatically rolling;

● When the packaging size changes, the adjustment is very simple by rotating the hand wheel without changing molds and bag makers;

● Different size products can also be packaged combinations to achieve the promotional effect;

● Using original Autonics digital temperature controller which built-in PID function. Sealing blade temperature is extremely sensitive and accurate and we can be arbitrarily set. Do not worry about hurting the product for imprecise temperature. The sealing blade itself is also quipped with automatic protection function which effectively prevent from accidental cutting;

● The machine is equipped with organic glass shield with automatic alarm function which greatly improves safety;

● The entire machine realizes unmanned operation with the production line connecting;

● Film up-down synchronization mechanism specially designed to correct the deviation film;

● I can be added easily tear functions according to customer requirements;

●Applies to software, food, cosmetics, printing, pharmaceutical, flooring, ceramic, beverages, hardware and other industries’ large quantities of shrink wrap.

LAYOUT

We can offer customized machine according to the size of your products!

We can replace the configuration according to your needs!